Ghost harvesters mar farm mechanisation programme

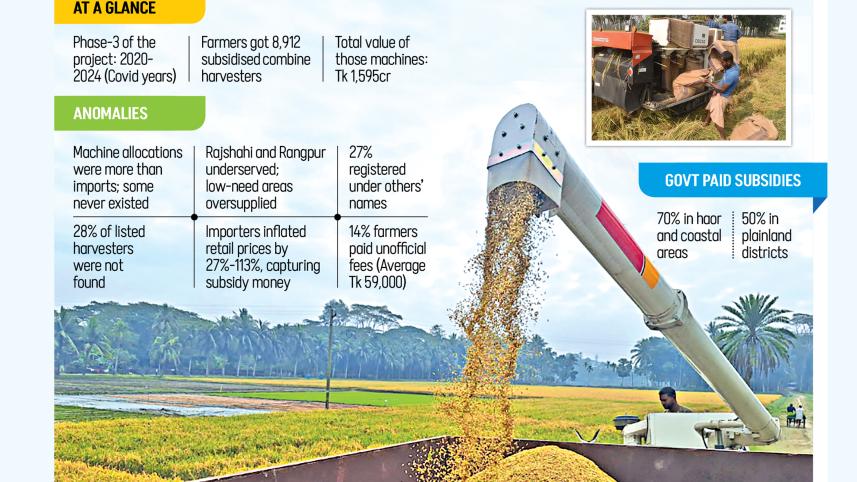

During the Covid pandemic, the authorities provided subsidies for nearly 9,000 combine harvesters to increase production, modernise farming and reduce the sector's dependence on intensive labour.

Now, a new report by the International Food Policy Research Institute (IFPRI) has identified half a dozen anomalies in the three-year programme.

Based on survey work, field research and administrative records, the report found that 28 percent of the harvesters distributed under the programme could not be traced.

Researchers compared import data from the revenue board with distribution records from the agricultural extension department and found that combine harvester distribution crossed actual imports.

This suggests that there were instances of "ghost machines" that were never distributed.

The findings also include fake ownership, bribes paid by farmers, inflated prices set by importers and uneven distribution across regions.

The findings were presented yesterday at a policy dialogue at the Bangladesh Agricultural Research Council in Dhaka's Farmgate area. The event was jointly organised by IFPRI and CIMMYT with support from CGIAR and the Bill and Melinda Gates Foundation.

Under Phase III of the Agricultural Mechanisation Support Programme, which ran from 2020 to 2024, the government distributed 35,347 subsidised machines.

Of these, 8,912 were combine harvesters worth a total of Tk 1,595 crore. The average cost was about Tk 18 lakh per unit, with the government covering 50 percent to 70 percent of the retail price. Combine harvesters alone accounted for 84 percent of the programme's total subsidy value.

Even so, the study found that 14 percent of the combine harvesters did not appear in official records and 27 percent were registered under names that did not match the actual owners.

A further 14 percent of applicants said they had paid unofficial fees averaging Tk 59,000 to get their machines.

The report also found price markups by several importers, ranging from 27 percent to 113 percent. Yet the programme showed positive results in areas where allocations were high. Rice farmers recorded yield improvements of between 6 percent and 13 percent.

Labour costs fell by 38 percent to 70 percent and overall production costs dropped by 12 percent to 26 percent.

Machinery service providers covered an average of 84 hectares a year and earned yearly profits of nearly Tk 489,530.

The report said there was no clear evidence of labour displacement. Agricultural employment remained stable, although workers gradually shifted toward self-employment.

However, financing remains a major obstacle. While 68 percent of machinery service providers borrowed money, only 6 percent accessed formal banking. Restrictions on using harvesters as collateral and informal lending rates as high as 22 percent further limited access.

IFPRI researchers recommended cutting import tariffs by up to 25 percent, supporting local manufacturing, digitising subsidy systems, requiring after-sales service, and offering tailored financial products such as hire purchase and seasonal credit.

At yesterday's programme, Mohammad Emdad Ullah Mian, agriculture secretary, said, "More than 25 upazila-level agriculture officers have been suspended for alleged irregularities in the mechanisation project."

He said the case has been referred to the Anti-Corruption Commission (ACC) for further investigation following concerns about procurement flaws, inflated machinery prices and weak oversight.

"There are systemic issues that must be addressed," said Mian. "Several of my colleagues became unintended victims of a flawed process. While not all were directly involved, the lack of preparation led to serious consequences."

He said future projects would be guided by feasibility studies and regional needs, with stronger governance at every stage.

Wais Kabir, consultant at CIMMYT and former executive chairman of BARC, said the project exposed serious weaknesses in planning and governance. "Engineers were not placed in key roles, and district officials were often unaware of the project's implementation status."

Kabir also criticised the heavy emphasis on combine harvesters, which received 70 percent subsidies, while other equipment, such as dryers and planters, received far less support.

He urged the government to restore mechanical support services, strengthen local manufacturing and ensure proper testing and standardisation.

Owen Calvert, project leader of the Sustainable Agrifood Systems Programme at CIMMYT, stressed the need for closer collaboration among all stakeholders. Citing examples of cooperation between microfinance institutions, MSPs, parts suppliers and manufacturers, he described the mechanisation ecosystem as "connected, collaborative, and inclusive."

Calvert summarised stakeholder recommendations, including reducing over-reliance on subsidies, removing import duties, expanding after-sales service, and introducing affordable financing.

"Mechanisation cannot succeed in silos," Calvert said. "Every link in the chain must be strengthened for sustainable success."

Md Mahmudur Rahman, additional secretary of the agriculture ministry, said the government would prioritise locally produced equipment to reduce costs and support the domestic industry.

He added that deliberate misuse of funds would face penalties, although those caught up unintentionally in the process would not be punished.

Among others, Md Abdus Salam, executive chairman, BARC, Md Ruhul Amin Talukder, senior policy advisor at IFPRI, Md Mahmudur Rahman, additional secretary at the agriculture ministry, and Timothy J Krupnik, CGIAR country convener and CIMMYT representative for Bangladesh, addressed the event.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments