Supply Chain and AI: Charting the next frontier for Bangladesh

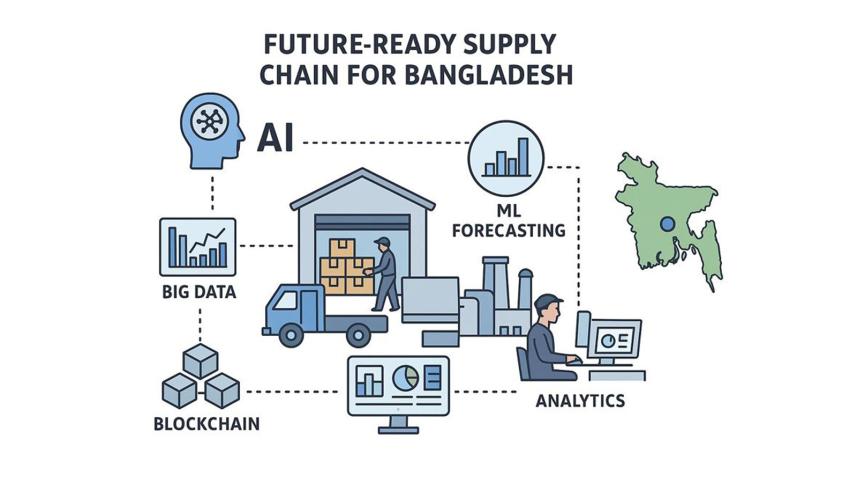

The supply chain is no longer a behind-the-scenes function. Once confined to warehouses and transport corridors, it now sits at the center of global competitiveness. From the shelves of Walmart in Houston to the garment factories of Gazipur, supply chains are being reshaped by data, digitalization, Big Data and above all, Artificial Intelligence (AI).

As the world adjusts to disruptions—from pandemics to port congestion and geopolitical tensions—supply chains are evolving from linear models of procurement and delivery to dynamic, intelligent ecosystems powered by system analytics and predictive intelligence. For Bangladesh, whose economy is deeply tied to the ready-made garment (RMG) sector, the question is not whether to adopt AI, blockchain, Big Data and advanced analytics—but how quickly.

Supply Chains in Transition: From Reactive to Predictive

Traditionally, supply chains were managed through manual forecasting, spreadsheet-based planning and just-in-time (JIT) strategies. These methods worked in relatively stable environments but struggled in today's volatile world.

In contrast, the modern world has embraced Industry 4.0 practices, where supply chains are increasingly data-driven, automated and predictive. Firms rely on system analytics to integrate Big Data streams—from IoT sensors in warehouses to global shipping metrics—and use machine learning models to forecast demand, optimize production schedules and simulate entire networks through digital twins.

For instance, a retail giant can now forecast winter jacket demand by analyzing weather data, social media sentiment, historical sales and global supply trends in real time. AI-powered systems, fed with Big Data, then adjust supplier orders, warehouse capacity and last-mile logistics automatically. This transition—from reactive management to predictive and prescriptive planning—has set new global standards.

Machine Learning Forecasting: The Backbone of Smart Supply Chains

At the heart of this transformation is machine learning (ML)-based demand forecasting, enhanced by Big Data and system analytics. Unlike traditional statistical models that rely on linear assumptions, ML techniques learn from massive structured and unstructured datasets to uncover hidden patterns. Common approaches include:

- Regression Models (Linear & Logistic Regression): Forecast sales using price, promotions, seasonal factors and system-generated insights.

- Time-Series Models (ARIMA, SARIMA): Enhanced with ML to capture seasonal shifts, market volatility and operational bottlenecks.

- Neural Networks (RNNs & LSTMs): Predict long-term demand by analyzing complex relationships across historical data, weather patterns, social media signals and Big Data feeds.

- Ensemble Methods (Random Forest, Gradient Boosting): Combine multiple models to improve forecast accuracy in volatile environments.

- Reinforcement Learning: Continuously adapts production schedules by learning from real-time outcomes such as supply delays or sudden demand spikes.

In today's world, these models are embedded in retail and manufacturing platforms. In Bangladesh, ML forecasting powered by Big Data analytics could help RMG manufacturers cut overproduction, reduce markdowns and respond rapidly to buyer demands.

"Forecasting used to mean looking at last year's data and adjusting by 10%. Now it means running neural networks across thousands of variables," says Mahbubul Alam, a supply chain consultant in Dhaka. "That's a huge leap—and it's one Bangladesh cannot afford to miss."

The Bangladesh Reality: Potential vs Preparedness

Bangladesh has made extraordinary strides in becoming a global manufacturing hub, but its supply chain practices remain uneven. In RMG, manual demand planning, fragmented ERP systems, and limited visibility across suppliers often result in inefficiencies. Logistics networks, though improving with projects like the Padma Bridge and upcoming Bay Terminal, are still constrained by congestion, delays and limited adoption of digital platforms, Big Data dashboards, and system analytics.

AI, Big Data and system analytics could change this trajectory. In garments, ML-driven demand forecasting could reduce dead stock and improve buyer alignment. In pharmaceuticals, inventory optimization using ensemble learning and predictive analytics could minimize expiry losses. In agriculture, LSTM-powered predictive models could synchronize harvesting with market demand, reducing food waste.

Large players are beginning to experiment. Ha-Meem Group has started integrating ERP systems with analytics platforms for better production planning. Beximco Pharmaceuticals is investing in Big Data-enabled digital platforms that could evolve into AI-driven inventory and compliance management. Meanwhile, logistics start-ups are testing Power BI dashboards linked with ML forecasting engines to track fleet performance and anticipate bottlenecks.

"AI, Big Data and system analytics are not just about efficiency—they are about credibility in the global market," says Faruque Hassan, President of BGMEA. "Our buyers increasingly demand transparency and sustainability. Without intelligent, digitally integrated supply chains, we cannot meet those expectations."

Blockchain: Ensuring Trust and Transparency

Global buyers demand traceability—knowing not just what product was made, but how and under what conditions. Blockchain, combined with system analytics, can revolutionize Bangladesh's supply chains, offering tamper-proof, end-to-end visibility from cotton sourcing in Africa to garment delivery in Europe.

Blockchain ensures that raw materials are ethically sourced, workers are paid fairly, and environmental standards are upheld. In the U.S., food companies use blockchain to trace produce "from farm to fork." For Bangladesh's RMG and seafood exports, similar systems, integrated with Big Data insights, could enhance compliance, strengthen reputation and enable real-time reporting to buyers.

"Blockchain helps us prove that our products are ethical and sustainable," notes a senior executive at Beximco Group. "This is not just about technology—it is about protecting our brand and ensuring long-term access to high-value markets."

Power BI and Data Analytics: Making the Invisible Visible

While AI and ML provide intelligence, data visualization and system analytics tools like Power BI make insights actionable. Supply chain managers in the U.S. rely on dashboards that consolidate ERP, IoT and logistics data streams in real time, showing:

- Inventory levels across multiple warehouses

- Supplier performance metrics

- Carbon emissions per shipment

- Real-time port delays

For Bangladesh, adopting such tools would be transformative. Imagine a Dhaka-based exporter monitoring factory output, Chattogram port clearance times, and New York buyer demand—all in one platform powered by Big Data and system analytics. Some Bangladeshi logistics firms are already piloting such dashboards to optimize delivery lead times and fuel consumption.

Three Key Shifts Defining the Future of Supply Chains

- From Efficiency to Resilience: Efficiency alone is no longer enough. AI-driven scenario planning and Big Data-powered simulations help companies anticipate disruptions—from container shortages to energy crises.

- From Cost Focus to Sustainability: Buyers in Europe and the U.S. tie procurement decisions to ESG metrics. AI-enabled carbon tracking, blockchain verification and system analytics ensure supply chains meet sustainability goals. For Bangladesh, this is critical—RMG exports must combine price competitiveness with environmental responsibility.

- From Localized Systems to Global Ecosystems: Supply chains are now digitally interconnected. Cloud platforms enable end-to-end visibility where suppliers, logistics providers and buyers operate on shared systems. Bangladesh must integrate into these ecosystems to remain competitive.

The Road Ahead for Bangladesh

The U.S. demonstrates what is possible when AI, ML forecasting, Big Data, blockchain and system analytics converge into intelligent supply chains. Bangladesh shows why it matters—for an export-led economy, supply chain excellence is about resilience, intelligence and survival.

To move forward, Bangladesh must:

- Invest in digital infrastructure, from ERP integration to cloud-based platforms

- Upskill the workforce in ML, AI, Big Data, Power BI and system analytics

- Adopt blockchain for compliance, transparency and traceability

- Encourage public-private partnerships to modernize logistics

With these steps, Bangladesh can leap from being a low-cost production hub to a smart, sustainable and globally competitive supply chain leader.

Final Word

The future of supply chains will be defined by intelligence, resilience and responsibility. ML forecasting will predict demand, AI will optimize operations, Big Data and system analytics will reveal actionable insights, blockchain will ensure trust, and data visualization will empower managers to make faster, smarter decisions.

For Bangladesh, the choice is clear: embrace this transformation now or risk being left behind. As BGMEA's Hassan puts it, "The buyers of tomorrow will choose suppliers not just on price, but on intelligence and integrity. That's why we must act today."

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments